Level Measuring

Level Transmitters :

Non-Contact Microwave:

- Plastic, aluminum or stainless steel housing

- Stainless steel parabolic, horn or plastic-coated antenna

- Plug-in graphic display module

- High-temperature variant

- 2-wire transmitters

- 25 GHz (K-band) measuring signal

- Non-contact level metering

- Accuracy up to ±3 mm

- Measuring range up to 23 m

- 99-point linearization

- Explosion-proof variants available

Capacitive:

- 2-wire compact transmitter

- High sensitivity

- Rod (0.2…3 m) or cable (1…20 m) probe

- Plastic, aluminum or stainless steel housing

- Partially or fully insulated probe

- Plug-in display module

- 32-point linearization

- Explosion-proof variants available

- Chemicals with dense gas layers above the surface

- High pressure, high temperature or vacuum

- Viscous or corrosive media

Hydrostatic Level:

- 2-wire compact transmitter

- Stainless steel diaphragm

- Accuracy: 0.25%

- High overload capability

- Level and pressure management

- High-temperature range

- Explosion-proof variants available

- Viscous or corrosive materials

- Chemicals with dense vapor or gas layers above the surface

Magnetostrictive:

- 2-wire compact transmitter

- 0.1 mm or 1 mm resolution

- Wetted parts: stainless steel or plastic

- Plug-in graphic display moduleHigh overload capability

- 99-point linearization

- Distance, level and volume measurement

- Explosion-proof variants available

- Interface measurementViscous or corrosive materials

- Chemicals, solvents, hydrocarbons

- Custody transfer measurement (OIML R 85)

Integrated Ultrasonic:

- 2-wire transmitter

- Non-contact level metering

- Narrow 5° beam angle

- Excellent signal processing via QUEST+ software

- Temperature compensation

- Secondary lightning protection

- 32-point linearization

- PP, PVDF, PTFE housing and transducers

- Explosion-proof variants available

- Level and volume measurement

- Open-channel flow metering

- Fail-safe indication

- For challenging applications such as vapor, fume, mixing blades, and light foam

Level Switches:

Float:

- Operation without power supply

- Low cost polypropylene level switch

- Airtight, dual-walled chamber

- Mercury-free microswitch

- Adjustable switch differential

- For low density liquids

Vibrating Fork:

- No moving parts

- Self-cleaning in most mediums

- Stainless steel and plastic coated probes

- Pipe extension up to 3 m

- Various output configurations

- High or low fail-safe mode

- Plastic, aluminum or Stainless steel housing

- Explosion-proof variants available

- For corrosive, thick, turbulent, flowing liquids

- Medium pressure: up to 40 bar

Vibrating Rod:

- No moving parts

- Self-cleaning for most mediums

- Stainless steel vibrating section

- Pipe extended (0.3…3 m) or flexible cable length (1…20 m)

- Plastic or aluminium housing

- Selectable density

- High or low fail-safe mode

- Selectable switching delay

- Dust-Ex models

- For grain, flour, plastic granules, cement, fly ash, etc.

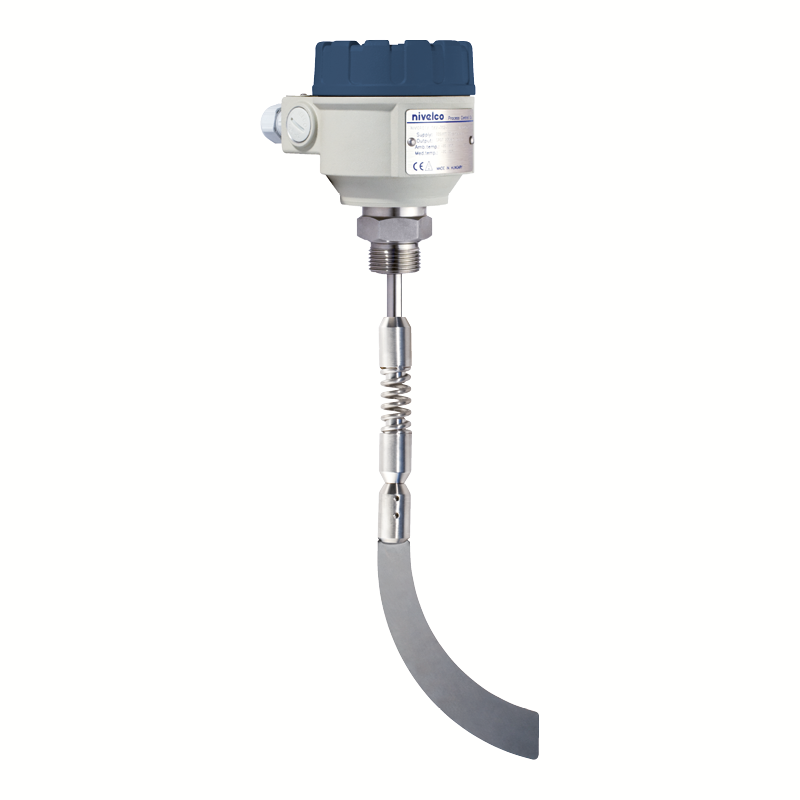

Rotary Paddle:

- Plastic or aluminum housing

- Long service time

- Motor shut-off feature

- Flexible coupling

- Solid rod or flexible cable extension (0.3…3 m)

- Sealed bearings

- High-temperature version

- Dust-Ex variants available

- High or low fail-safe

- Rotary force independent of the supply voltage

- High-temperature version

- Feed, coal, sand, rocks, limestone, metals, rubber

- Rotary force independent of the supply voltage

- Low supply voltage is indicated by a blinking LED

RF - Capacitance:

- Intelligent Electronic level switch

- Build-up immunity

- Easy calibration

- Selectable sensitivity

- Fail-safe operation mode

- Pipe (0.7…3 m) or flexible cable extension (1…10 m)

- High temperature version

- Dust-Ex models

- For high viscosity, sticky materials

- For special applications such as blockage detection in hopper and hot ash