Case Study- SI Group-India Private Limited – Navi Mumbai

Introduction-

Water systems are becoming increasingly complex and instrumented, necessitating a diverse range of capabilities to effectively deal with the complexity. Industrial process production requires accurate measurement of water for the assuring the quality material. The day by day the water demand is increasing and its is becoming costly. Hence, for the industry it is become necessary to measure the water and control the loss.

The Problem-

The customer has already installed the EMF Meters on Main Line and local make mechanical water meters on different internal lines. The old water flow meters installed in the plants are not accurate as per the standards. In addition to that at some places water meter’s manual reading is difficult for access. There are so many reasons underground locations, limited spaces can increase the risks of meter reading errors. Due to these reasons there was inaccuracy in main meter reading and the sub meters installed in the industry.

The customer has contacted Chem-Tech Associates to do the site visit and provide the proper solution for the same.

The Solution-

Chem-Tech Associates technical team has visited the plant and seen the site locations. The meters were installed in both safe as well as hazardous area. After careful inspection, the customer is suggested to replace the old local water meters with latest MID approved smart water meter with LoRaWAN sensor technology (for ATEX-Zone 2), for main line EMF Meters the GSM Datalogger with IP protection and web based AMR / IoT Software on SAAS Platform.

As a result, the customer has started getting the proper accurate reading as well as data for the analytics. The customer is satisfy with the solutions provided by Chem-Tech Associates.

Case Study- Bhadreshwar Vidyut Pvt. Ltd. – Kutch

Introduction-

The important emissions from coal combustion include carbon dioxide (CO2), nitrogen oxides (NOx), sulfur dioxide (SO2), air-borne inorganic particles such as flyash, and other trace elements, especially mercury. Estimated emissions of major pollutants from coal-based power plants in the country are: 1.6 million tonnes of particulate matter, 1.5 million tonnes of NOx and 3.0 million tonnes of SO2 every year and whopping over 160 million tonnes of flyash generation. These are large quantities. If we do not recognize this enormous environmental issue and not invest in technology, we pay through increased human morbidity and mortality. Science tells that sulfur and nitrogen oxides convert into fine particles of sulfates and nitrates posing greater health problem than the precursor gases sulfur and nitrogen oxides. For the same measurement of the same is to be done in Ambient Air within plant premises.

The Problem-

The customer has already installed CEMS system for the stack gas measurement but does have any instrument for the measurement of AQI.

The customer has contacted Chem-Tech Associates to do the site visit and provide the proper solution for the same.

The Solution-

Chem-Tech Associates technical team has visited the plant. After visit and discussion with customer Chem-Tech Associates has suggested installing the CAAQMS for the SO2, PM 2.5 and PM 10 as per the latest CPCB Guidelines.

As a result, the customer has finalized the order of CAAQMS with the latest technology and advance features like the compact design, inbuilt AC, single phase operated etc.

Chem-Tech Associates has completed the commissioning of the system in 2019 and till today it is working successfully.

Case Study- Siddhi Vinayak knots & Prints Pvt. Ltd. – Surat

Introduction-

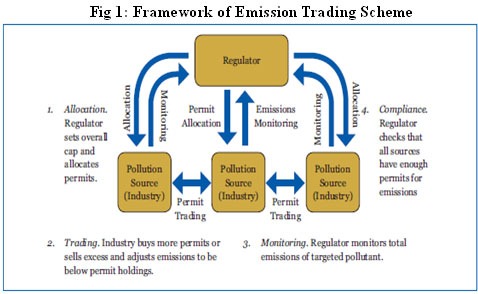

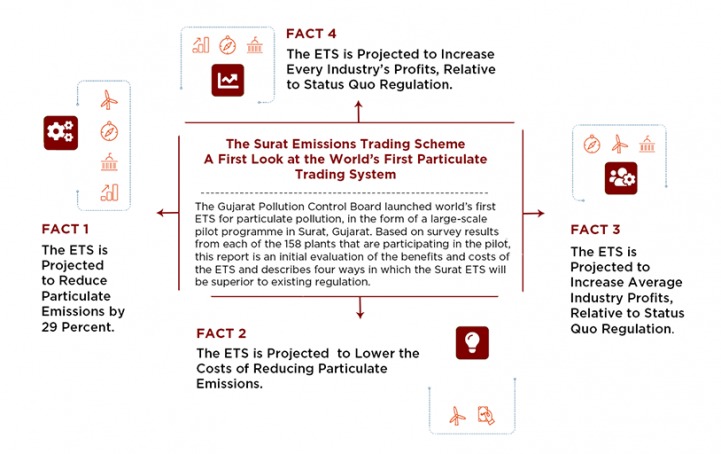

An emissions trading scheme (ETS) is a regulatory tool used to reduce pollution emissions at a low overall cost. In such a scheme, the regulator sets the overall amount of emissions but does not decide what any particular source will emit. Industrial plants and other polluters, rather than being told a fixed emissions limit, face a price for their emissions and choose how much to emit, within reasonable limits, taking this price into account. The price of emissions makes pollution costly and gives polluters an incentive to cut back. Emissions trading schemes have great potential to lower pollution while minimizing costs for industries.

The Problem-

The customer has to installed PM CEMS system for the PM measurement in stack as per the ETS Project guidelines.

The customer has contacted Chem-Tech Associates to do the site visit and provide the proper solution for the same.

The Solution-

Chem-Tech Associates technical team has visited the plant. After visit and the process data provided by the customer Chem-Tech Associates has suggested the Back Scattered Type PM CEMS concentration device and a flow meter device as per the requirement of ETS project.

As a result, the customer has finalized the order of PM CEMS and Chem-Tech Associates has completed the commissioning of the system in 2018 and till today it is working successfully.